Machines - Robots - Automobiles - Energy - Never Ending Technology - Power - Go Green - Pumps - Compressors - Power Plant - CAD - Cooling Tower - Oil & Gas - Heat Exchangers - Interview - Mock campus - Ship - Materials ...

INSPECTION OF BOILER WATER HEADERS

Each handhole and handhole plate seat should be examined

for erosion, steam cutting, tool marks, and other damage that might permit

leakage. If the plate has leaked previously, it should be checked for trueness

and possible deformation. Seating surfaces and faces of handholes should be

examined for cracks. It may be necessary to use a hand mirror to inspect the

handhole seats.

The inside surface of the headers should be inspected for

corrosion and erosion. The location and amount of scale buildup should be

noted, and the tube ends should be checked for pits, scale, cutting or other

damage from tube cleaners, and deposit buildup. If there is considerable scale

or deposit buildup, the flow may be restricted to the point that tubes become

overheated because of insufficient circulation. Deposits and scale should be

removed with a scraper and the depth of coating determined. Lower waterwall

headers are particularly susceptible to heavy deposit buildup.

Downcomers and risers should also be inspected for this

type of deposit. Thickness readings of headers should be obtained periodically

by ultrasonic technique. The headers should be calipered whenever tubes are

removed.

External surfaces of headers should be examined either

directly or indirectly with mirrors, and particular attention should be paid to

the points where tubes enter the header for indications of leakage from the

tube roll. The header surfaces adjacent to tube rolls and handholes should be

inspected for cracks. If external inspection of headers reveals pitting,

thickness measurements should be made using ultrasonic techniques.

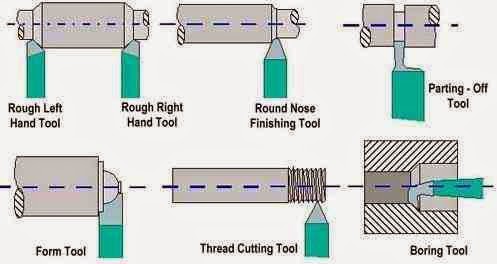

Types of Cutting Tool

Rough Left Hand Tool

Rough Right Hand Tool

Round Nose Finishing Tool

Parting - Off Tool

Form Tool

Thread Cutting Tool

Boring Tool

MAGNETIC TEST FOR CARBURIZATION

Austenitic

tubes are essentially nonmagnetic. Carburized areas of the tubes become

magnetic, and if these areas are large, they can be detected with a magnet. A

magnet on a string dropped down a tube will indicate areas that are magnetic

but will not indicate the depth of carburization. There are several

commercially available devices that are used for measuring the ferrite content

of austenitic welds which may be suitable for identifying loacilized areas of

magnetism in heater tubes. Some

instruments and field services can relate the degree of magnetism to the depth

of carburization. Most of the instruments are proprietary, and the field

services are limited.

A rule of thumb states that up to 50% carburization can

be tolerated on stream before loss of strength materially affects tube life.

Although this rule of thumb indicates that a tube with 50% carburization should

be replaced, it does not mean that less than 50% carburization will allow the

tube to remain in service until the next shutdown. Factors including the rate

of carburization, the expected service time until the next shutdown, the amount

of excess metal, and changes in pressure and temperature must be taken into

account.

PIT DEPTH MEASUREMENTS

General pitting of the external tube surface should be

evaluated with a pit depth gauge to assess the depth and to estimate a pitting

rate. The gauge should be used in conjunction with an ultrasonic thickness

gauge to more accurately determine remaining wall thickness. Scale on the tubes

will mask pits and so it is prudent to remove scale in selected areas to find

the deterioration.

Subscribe to:

Posts (Atom)