The carbon equivalent (CE) is a crucial metric used to assess the weldability of steels. It provides a simplified measure of how alloying elements, particularly carbon and other hardening elements, affect the steel's tendency to harden during welding. Higher CE values generally indicate a greater propensity for hardening, which can lead to potential issues like cracking or distortion.

Common CE Formulas

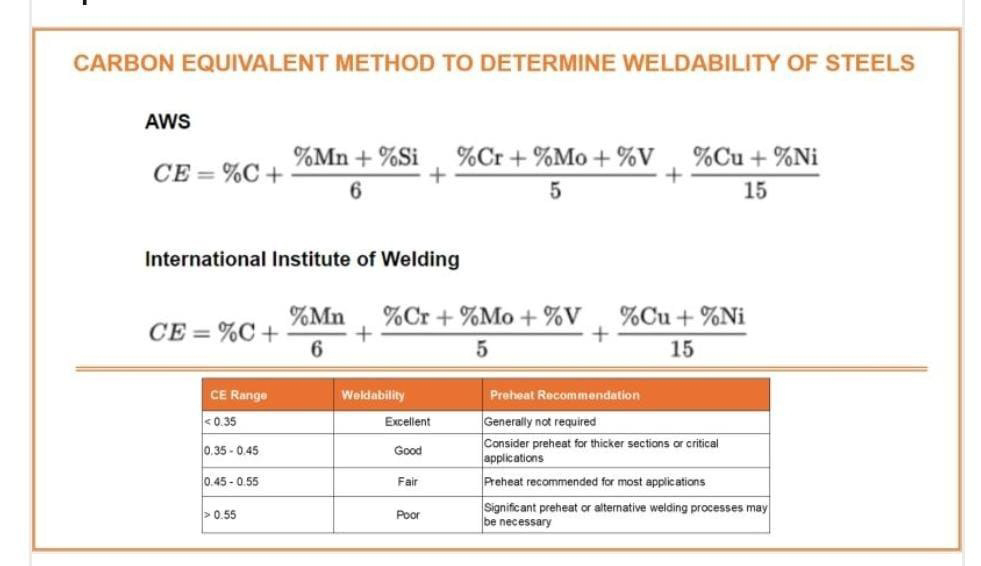

Two primary CE formulas are widely recognized:

American Welding Society (AWS) Formula: Includes silicon as a hardening element.

International Institute of Welding (IIW) Formula: Excludes silicon.

What is Weldability?

Weldability is a complex term that encompasses more than just the ability to join metals through welding. It also refers to the material's suitability for a specific application and its performance under the intended service conditions. A weldable material can be successfully fabricated using welding techniques and will function adequately in its intended environment.

CE and Preheat

CE and Weldability: Lower CE values generally correlate with better weldability due to reduced hardening tendencies.

Preheat and High CE: For steels with high CE values, preheating is often necessary to prevent excessive hardening and potential cracking. Preheat helps to control the cooling rate and reduce the risk of rapid cooling-induced hardening.

CE Ranges and Preheat Recommendations

The following table provides a general guideline for CE ranges and corresponding preheat recommendations:

No comments:

Post a Comment